FourT6and2

Well-known member

I'm building a Superlead clone and I was playing around with some different wiring methods. I don't care about doing it the "traditional" way or being period correct. My main goal is for it to sound good and for the wiring/layout to be clean.

I was looking at a bunch of Soldano SLO builds and they are so clean and the wiring looks immaculate. Mainly, the heater/filament wiring in the preamp and poweramp. If you don't know, the SLO uses parallel runs of bus wire to connect everything instead of twisting the wires. The result is a much cleaner and more simple build. The SLO does not run DC current... it's still AC. Most people say the wires are usually twisted to cancel out any noise or Back EMF. So, how does Soldano get away with it? I've played 3 or 4 SLO's and they've all been fairly noise-free for a high(er)-gain amp.

I'd like to utilize some build/wiring methods from the SLO in my Superlead build. So, I'd like to invite those of you in the know to discuss the pros/cons of using this type of wiring method. Obviously, in an SLO the tube sockets are installed with them rotated so that the corresponding pins all line up in a straight line so a bus wire can be used.

In addition to just the heater wire, most of the other pin connections utilize this method as well. So that's a plus. These things are just soooo cleanly built, I'd like to move away from the messy wiring of old Marshalls and build something that's super clean.

Here are some examples:

And here's a similar example from Hiwatt:

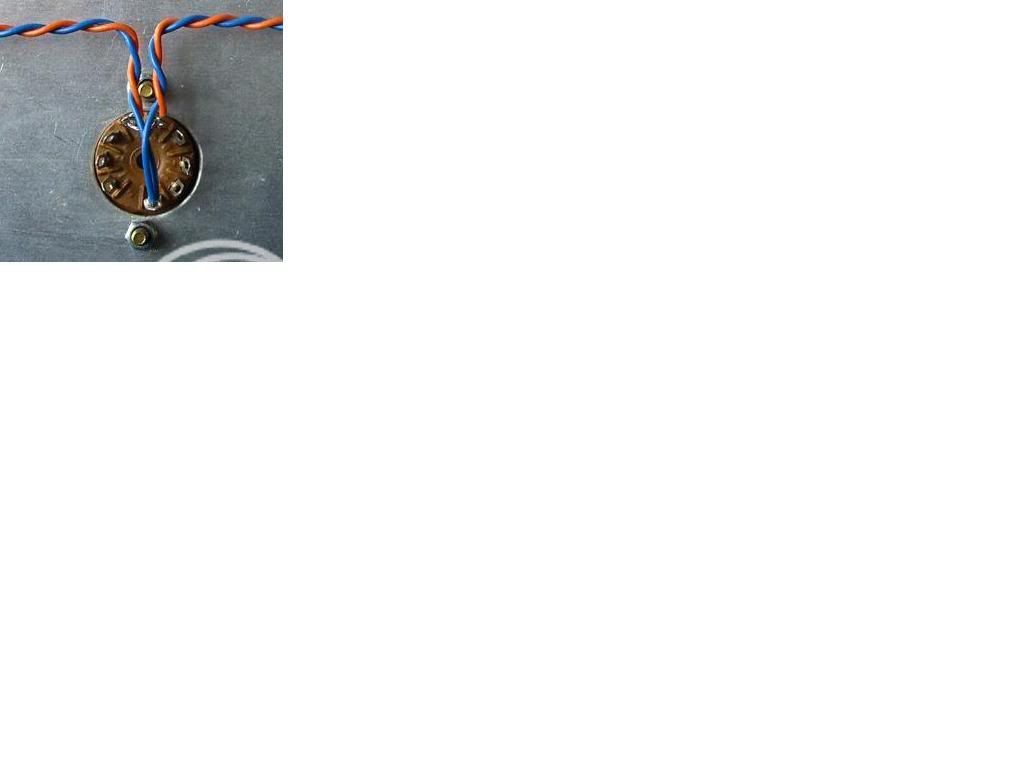

As opposed to something typically seen, like this:

I was looking at a bunch of Soldano SLO builds and they are so clean and the wiring looks immaculate. Mainly, the heater/filament wiring in the preamp and poweramp. If you don't know, the SLO uses parallel runs of bus wire to connect everything instead of twisting the wires. The result is a much cleaner and more simple build. The SLO does not run DC current... it's still AC. Most people say the wires are usually twisted to cancel out any noise or Back EMF. So, how does Soldano get away with it? I've played 3 or 4 SLO's and they've all been fairly noise-free for a high(er)-gain amp.

I'd like to utilize some build/wiring methods from the SLO in my Superlead build. So, I'd like to invite those of you in the know to discuss the pros/cons of using this type of wiring method. Obviously, in an SLO the tube sockets are installed with them rotated so that the corresponding pins all line up in a straight line so a bus wire can be used.

In addition to just the heater wire, most of the other pin connections utilize this method as well. So that's a plus. These things are just soooo cleanly built, I'd like to move away from the messy wiring of old Marshalls and build something that's super clean.

Here are some examples:

And here's a similar example from Hiwatt:

As opposed to something typically seen, like this: