B

Bordonbert

New member

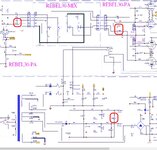

Hi guys. I'm working on a Rebel 30. Never had one under my hands before so I'm not up to speed with any unique wrinkles.

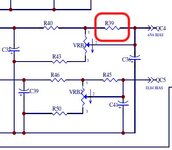

It has a problem in the 6V6 side where it warms up and plays fine for about 10 seconds then noise fades in over the signal increasing over about another 10secs to very loud when it blows the HT fuse. This is the correct 315mA value. It is definitely in the 6V6 circuitry as the EL84 side works fine with the 6V6s pulled. I'm assuming that this is simply the bias increasing to a ridiculous level due to the fault.

I have a set of 6V6s on order in case it turns out to be just a valve issue but it could also be down to the bias circuitry itself or even the signal series DC blocking caps around the mix section becoming leaky. I'm suspecting C5/7/13/14/36 as obvious candidates. Are there any other peculiarities about this amp that anyone knows of which could cause this issue and should be checked?

It has a problem in the 6V6 side where it warms up and plays fine for about 10 seconds then noise fades in over the signal increasing over about another 10secs to very loud when it blows the HT fuse. This is the correct 315mA value. It is definitely in the 6V6 circuitry as the EL84 side works fine with the 6V6s pulled. I'm assuming that this is simply the bias increasing to a ridiculous level due to the fault.

I have a set of 6V6s on order in case it turns out to be just a valve issue but it could also be down to the bias circuitry itself or even the signal series DC blocking caps around the mix section becoming leaky. I'm suspecting C5/7/13/14/36 as obvious candidates. Are there any other peculiarities about this amp that anyone knows of which could cause this issue and should be checked?