pipelineaudio

Active member

What’s the reason for 63/37? I’ve only used 60/40 and sometimes have to use ROHS compliant if the products are going to Europe and I am horrible with it compared to 60/40

What’s the reason for 63/37? I’ve only used 60/40 and sometimes have to use ROHS compliant if the products are going to Europe and I am horrible with it compared to 60/40

Awesome! After a lifetime of soldering patch bays and all manner of nastiness, I never really thought about the hows and whys of the solder itself! I gotta try some. And probably time for a new iron.60/40 solidifies over a range of temperatures. That means as it transitions from liquid to solid, it goes through a plastic state where it's kind of pasty and slushy. If you disturb the joint during this transition, you get a bad (cold) joint. 63/37 is eutectic, which means it both melts and freezes at one specific temperature. Therefore, it sets and transitions much more quickly and all at once. That means fewer cold joints. It also means lower heat is needed, which is better for sensitive components.

Yeah I bought one of those a year or so ago and it was a pretty big upgrade for me..... I really like how it gets to temperature fast and gives a constant temp reading......Previously was using 40 watt Radio Shack irons........built 6 amps with them and numerous repairs....I love my Weller WE1010NA.

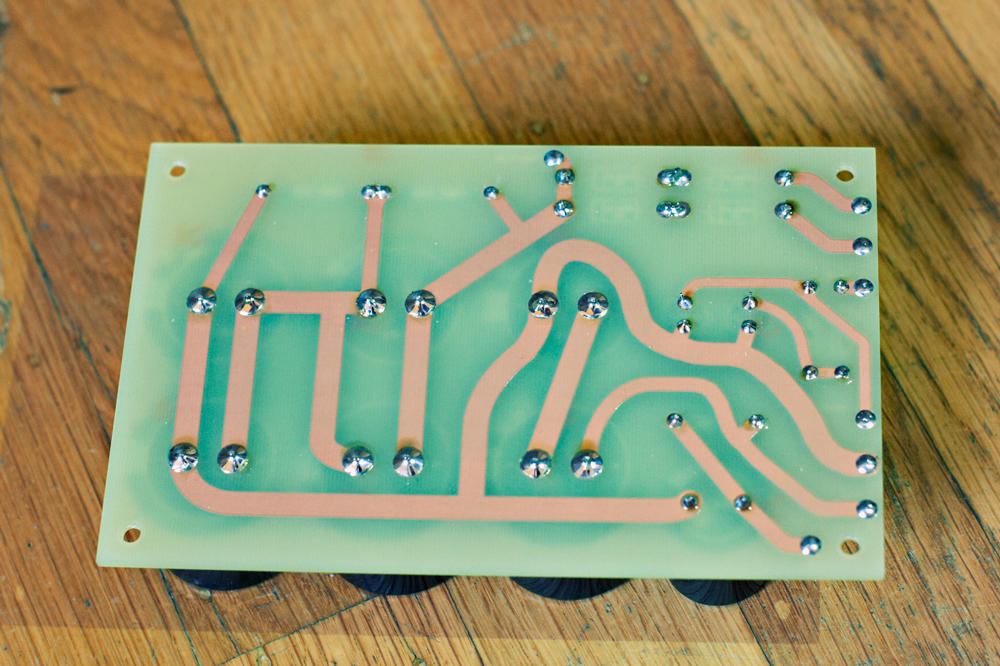

View attachment 405124

I wish they had this colour when I ordered mine 15yrs ago

I want to try this but there are like 400 different kester 63/37 models. I want like 1.6mm. Which model number is correct, do you know?Kester 63/37 is the bees' knees.

1.6mm thick?? Damn dude, that is really thick stuff!!I want to try this but there are like 400 different kester 63/37 models. I want like 1.6mm. Which model number is correct, do you know?

It’s what I’ve always used for patchbays and mic cables and general studio repair but I’m open to trying different stuff. I’m getting the FX 888dx are there specific temp setting you would recommend for different solder thicknesses for like 1/4” jacks?1.6mm thick?? Damn dude, that is really thick stuff!!

I could not imagine going any higher than 1mm, and that is pretty up there. I run my Hakko @ 350 C and it works like a charm!It’s what I’ve always used for patchbays and mic cables and general studio repair but I’m open to trying different stuff. I’m getting the FX 888dx are there specific temp setting you would recommend for different solder thicknesses for like 1/4” jacks?

They have a table here for the "44" flux solders: https://www.kester.com/products/product/44-flux-cored-wireI want to try this but there are like 400 different kester 63/37 models. I want like 1.6mm. Which model number is correct, do you know?

I use the .8 mm core version of the stuff I recommended above, for just about everything. You'll have to feed more than you're used to, but there's a bit more control due to that. Haven't tried 1.6mm core so can't comment on specific differences. I'm usually cooking at 390C.It’s what I’ve always used for patchbays and mic cables and general studio repair but I’m open to trying different stuff. I’m getting the FX 888dx are there specific temp setting you would recommend for different solder thicknesses for like 1/4” jacks?