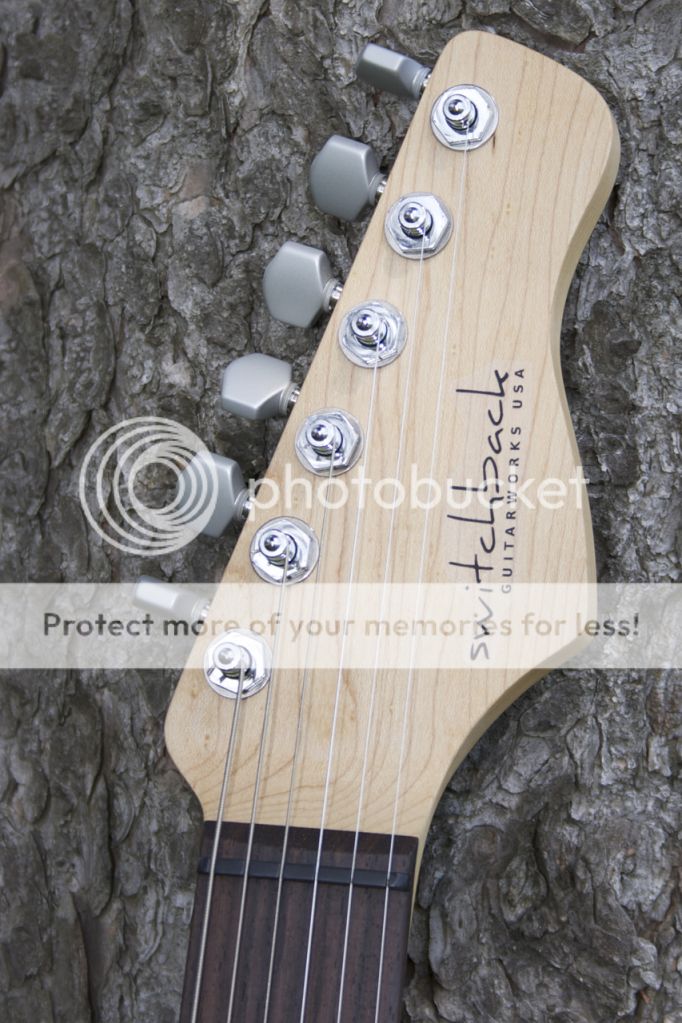

ratter

New member

Digital Jams":1bruchpy said:NOICE!

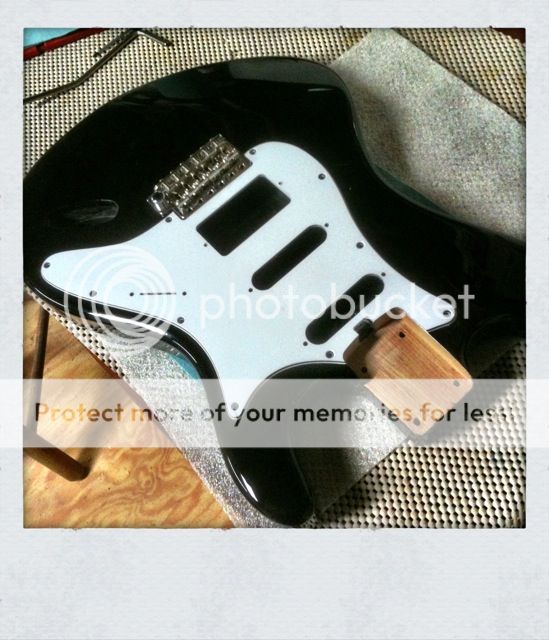

I see lots of bodies on the floor, anything worth anything??

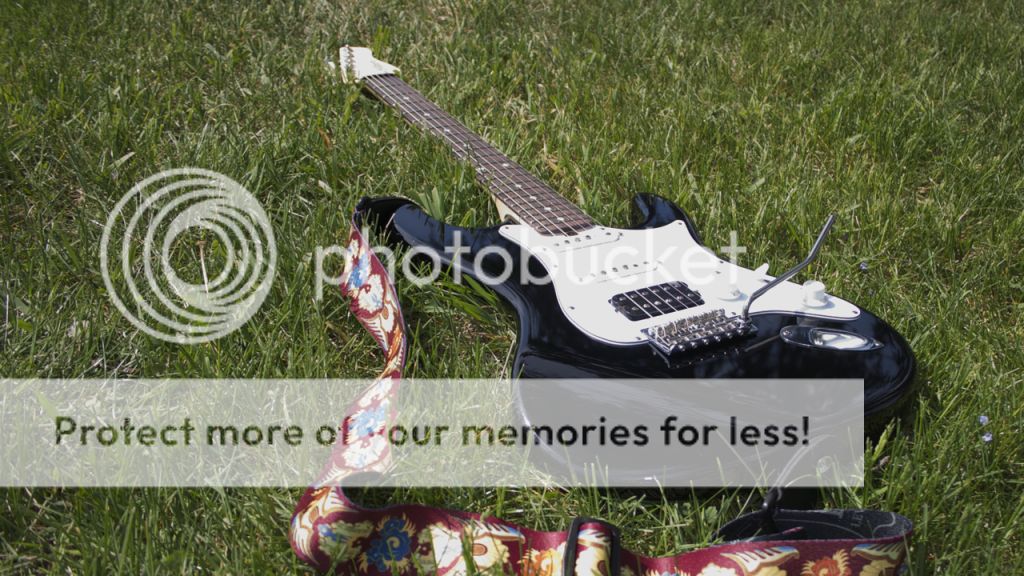

I am liking the Pacer influence, great playing comfortible design

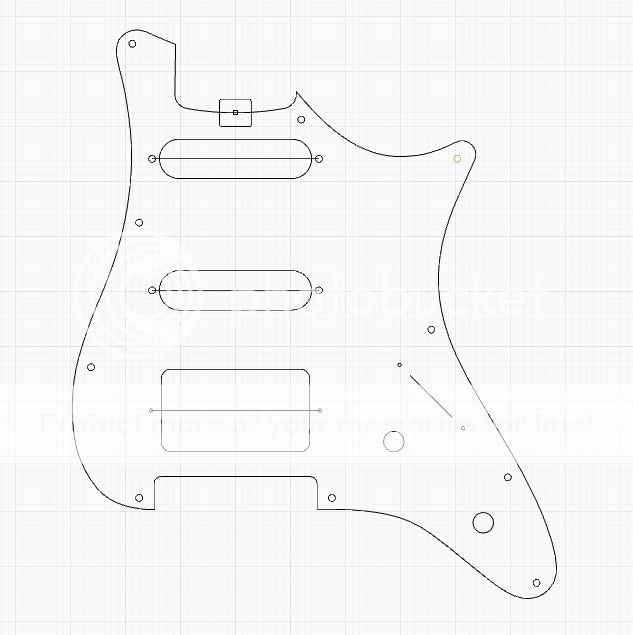

Nah...old test cuts piled here and there. Bodies, necks, guards, etc. The only other thing still in play is the setneck proto stuck on the wall there. It will see the light of day again hopefully fairly soon.